Where Tradition Meets Technology

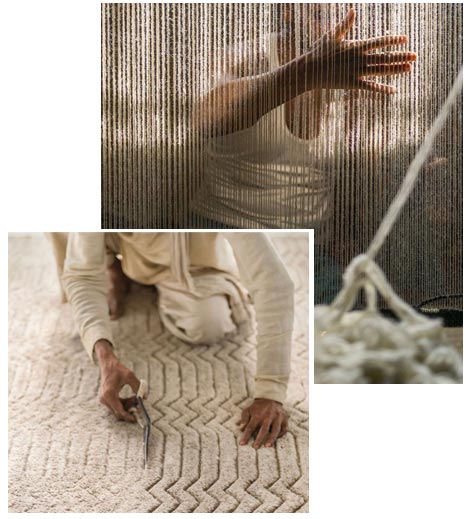

Our strength lies in a robust manufacturing infrastructure, blending modern technology with skilled craftsmanship.

Key Infrastructure Highlights:

Advanced Production Units – Equipped with high-speed tufting, weaving, and printing machines.

Design & Development Studio – In-house design team creating global trend-driven collections.

Quality Control Systems – Multi-stage quality checks to ensure international standards.

Warehousing & Logistics – Streamlined supply chain for timely global deliveries.

With continuous upgrades in machinery and training, we ensure scalability, precision, and innovation in every product we deliver.

Power Looms – 20 Units

High-capacity looms ensuring consistent fabric weaving with precision.

Pit Looms – 50 Units

Traditional handlooms preserving Panipat’s rich weaving heritage.

Frame Looms – 40 Units

Versatile looms for customized weaves and creative flexibility.

Tufted Machines – 110 Units

Specialized for tufted rugs and bathmats, delivering premium texture and finish.

FRS Machines – 2 Units

Advanced finishing systems for enhanced quality and durability.

TPR Machines – 4 Units

For advanced backing and finishing solutions, ensuring strength and stability.

Circular Knitting – 4 Units

Capable of producing flexible and innovative knitted fabrics.

Rapier Looms – 12 Units

Designed for creating intricate woven patterns with fine detailing.

Hot Melt Antiskid – 2 Units

Adding slip-resistant backing for safety and durability in rugs and mats.

Digital Printing – 2 Units

Delivering vibrant, trend-driven designs with sharp detailing.